- Home

- About PDV

- Main Business

- Products

-

Typical Projects

- 104MW Grid Connection HFO Power Plant in Iraq

- CNOOC LF14-4 DPP Crude Oil Main Power Plant

- Industry Park PPS in the Kurdistan Region of Iraq

- South Australia HFO Power Plant

- CNOOC LF12-3 FPSO Crude Oil Main Power Plant

- 100MW Grid Connection HFO Power Plant in Ecuador

- QHD32-6 CEPI/CEPJ Offshore Engineering

- 142MW Combined Cycle Power Plant in Bangladesh

- 138MW Combined Cycle Power Plant in Bangladesh

- CNOOC EP15-1 CEP Crude Oil Main Power Plant

- Fiji HFO Power Plant

- CNOOC LH11-1 FPS Crude Oil Main Power Plant

- East Timor Power Plant

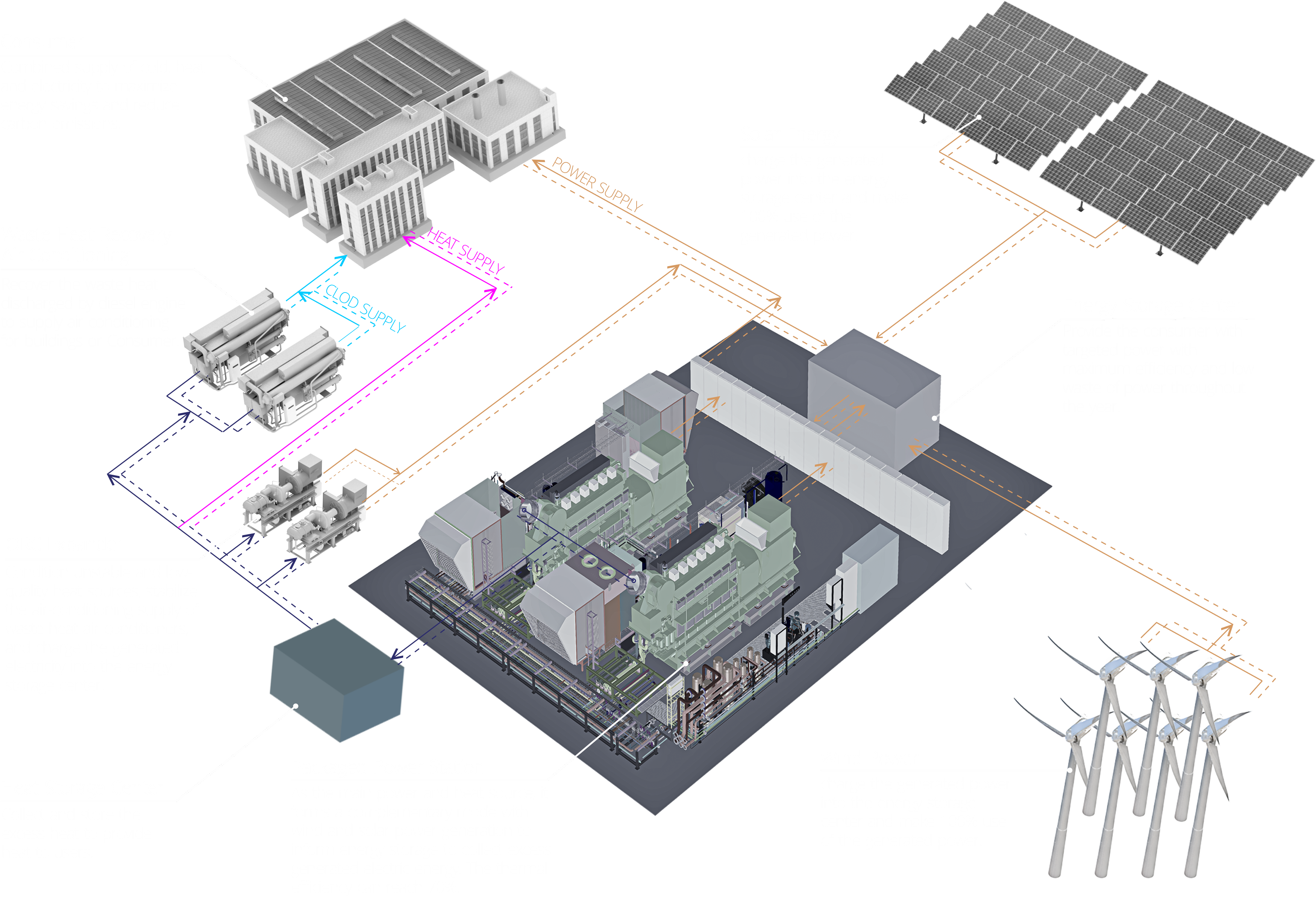

- 3D Digital

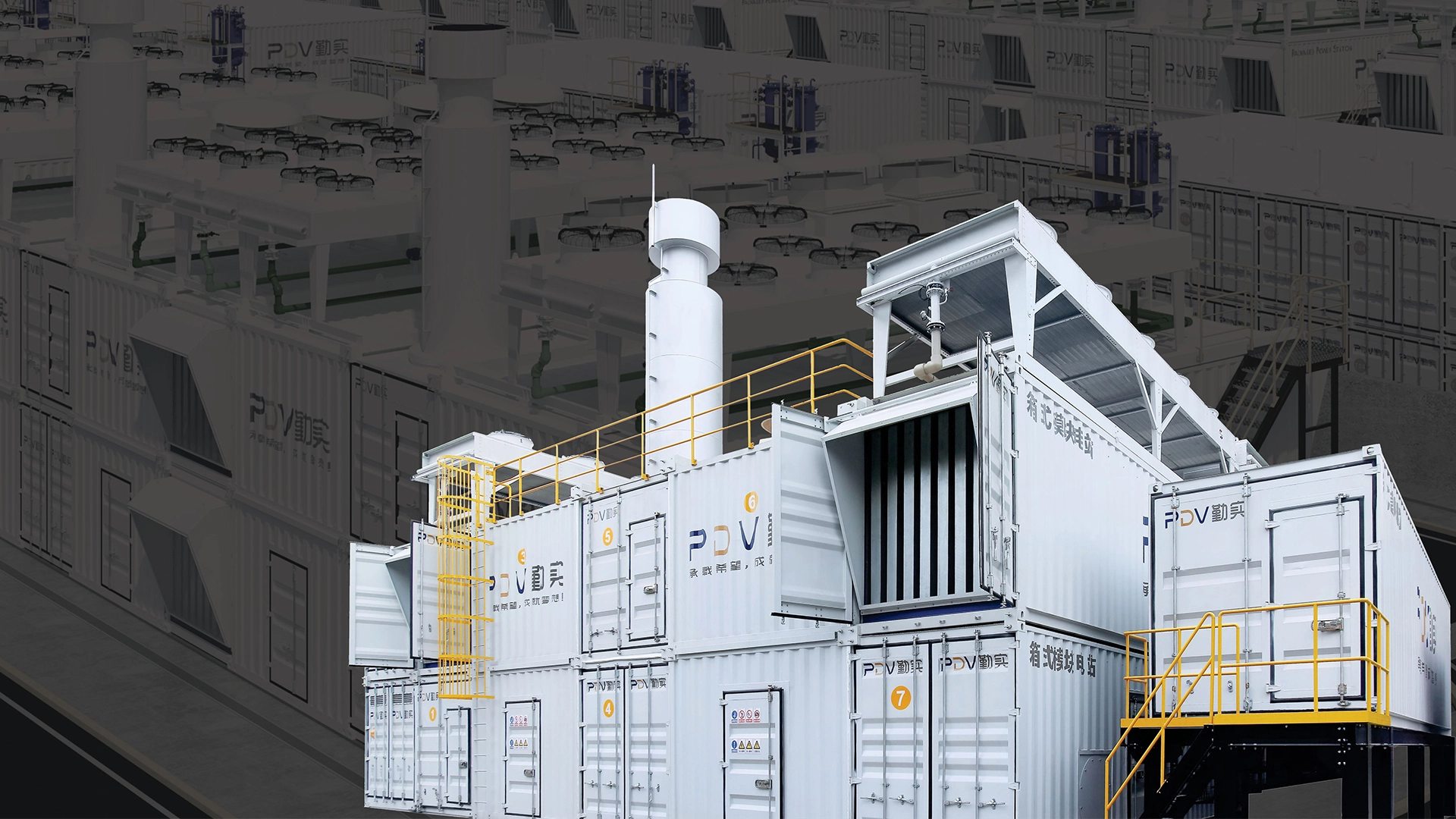

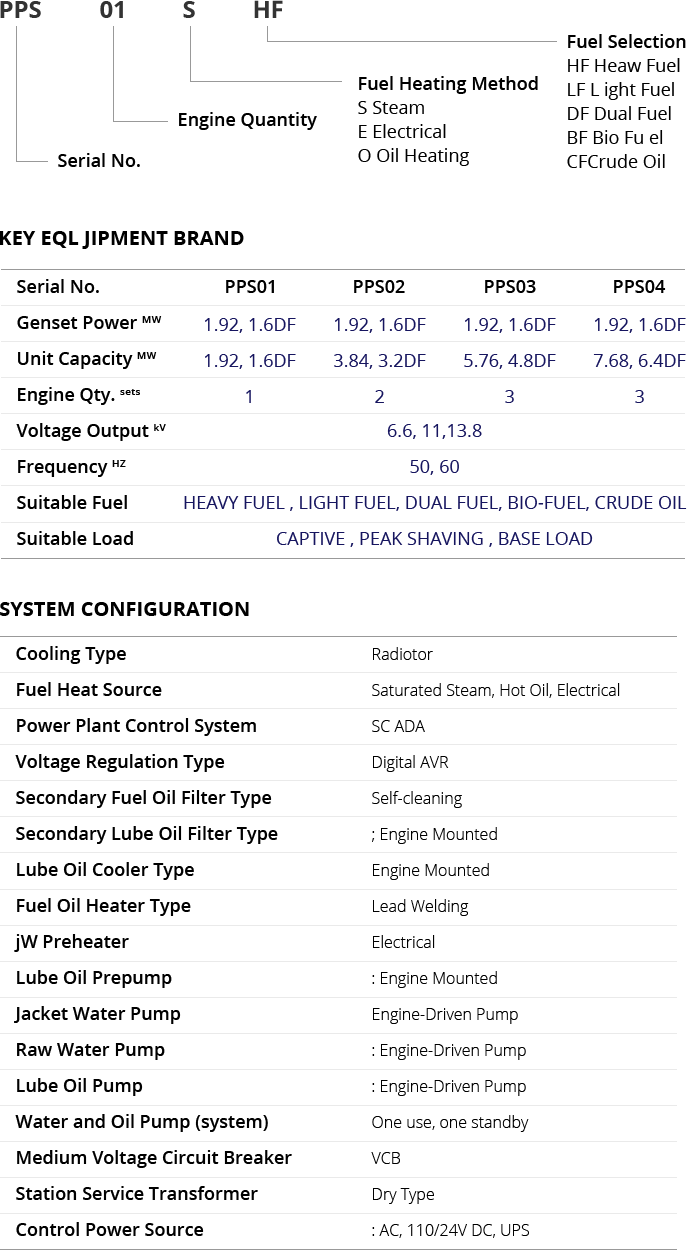

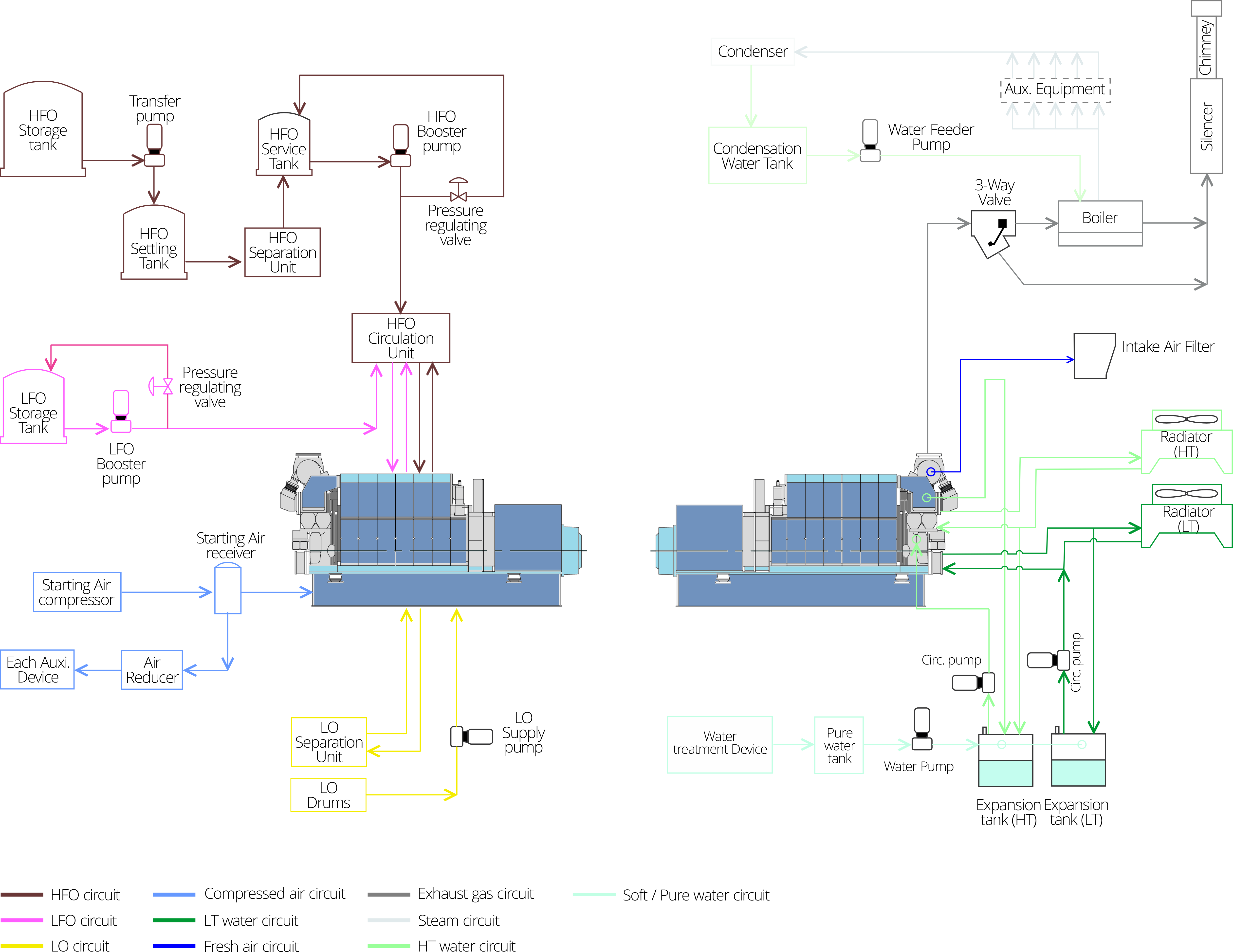

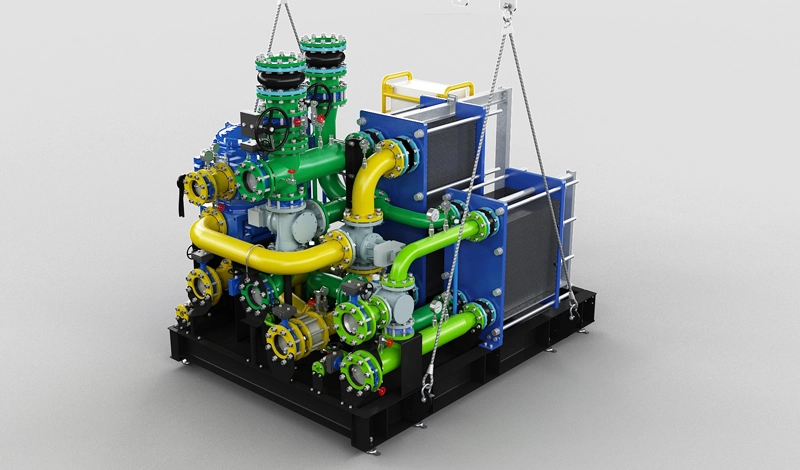

- PPS

- PDV Metals

CN

CN

en

en